Other applications for thermal lances

Within the general processes of a foundry there are several critical points, each of which contributes to the long process of obtaining refined metals. Among them, the tapping process undoubtedly occupies a special place.

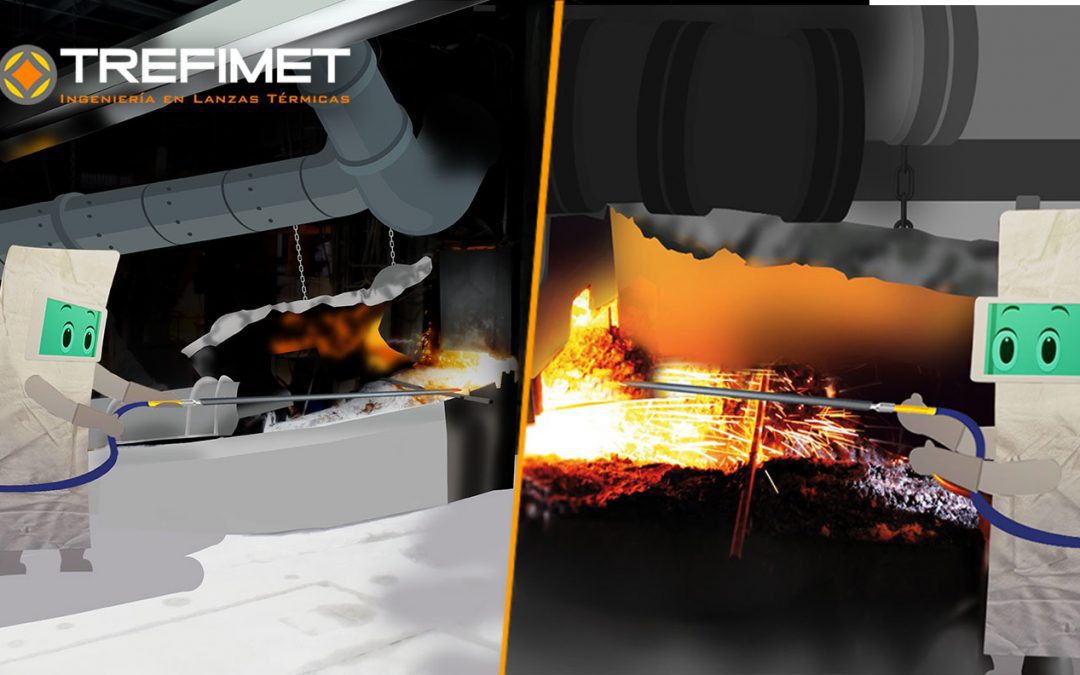

Tapping is the process of removing molten material from melting furnaces by opening the furnace passages. To achieve this, the material inside the passage is removed, which prevents molten metal from escaping from the furnace until the melting/conversion process is complete.

To carry out this operation, in most cases, operators use oxygen rods (hollow tubes) to melt the material that covers the passage, leaving the molten metal to flow freely from inside the furnace. Although this has been the practice for many years, there has been no noticeable improvement over the use of oxygen rods, with problems both in the care of the passageway components, and in the prolonged exposure of operators to glowing material and fugitive gases from the passageway. Both of these problems stem from the poor accuracy of the rods, as well as their poor performance when piercing materials by melting.

One possibility to deal with this situation is to use thermal lances, which have different configurations in their cross-section, which, as a consequence, allow high concentrated energy to be generated at the moment of ignition of these tools. By having this quality, they have the ability to pierce any material by fusion with precision and speed, minimising damage to the components of the passage. Moreover, thanks to this same feature, the operation can be done in a few minutes, which speeds up the overall operation and reduces the operator's exposure and time spent in the tapping area.