Other applications for thermal lances

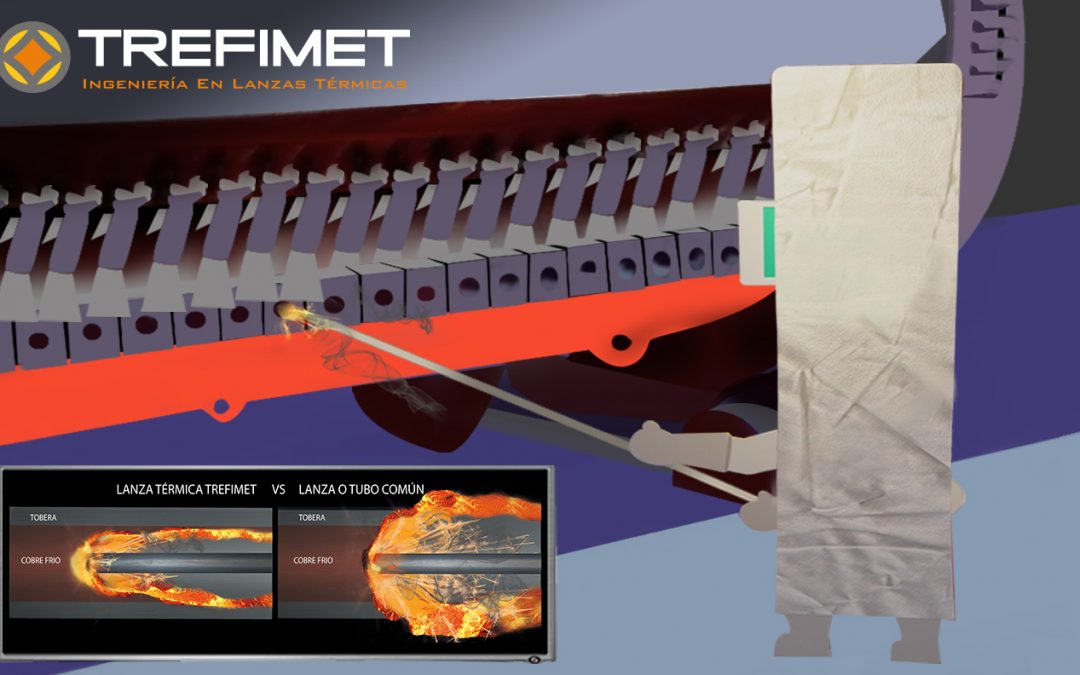

Within the copper world, there are pyrometallurgical reactors whose function is to carry out the smelting-conversion process or just conversion of copper concentrate by injecting enriched air through nozzles submerged in the liquid bath. This process is responsible for injecting oxygen into the liquid bath of concentrate in order to oxidise the iron and sulphur contained in the concentrate and "purify" the copper.

As the nozzles are in direct contact with the liquid concentrate bath, there are occasions where the nozzles fill with this material, preventing oxygen injection through the nozzle, which hinders the overall functioning of the reactor and makes the overall operation more inefficient.

Commonly, to remedy this situation, the nozzles are cut with oxygen lances in order to remove them and replace them with a new one, a cumbersome operation that delays the recovery of the nozzle position and momentarily disables the injection of enriched air to that area of the furnace.

For this operation there are Trefimet thermal lances, which, given their configuration, are able to maximise the generation of thermal energy and focus it, making them precision tools when perforating or cutting any material by fusion.

The precision delivered by these nozzles allows the material jammed in the nozzle to be cleaned without damaging its components, thus allowing the nozzle to be recovered without the need to change the nozzle or disable the injection position.

Compared to the traditional product, Trefimet thermal lances present substantial differences that result in a more precise and faster operation, contributing to the care of the nozzles and allowing their reuse.