Thermal lances and their tremendous contribution to the world of innovation in the

As in any industry today, innovation in mining is a key element of the sector's recovery and future success. Over the years it has become vital, as it gives companies an advantage to penetrate faster and better connect with developing markets, creating greater opportunities.

During 2015, a research survey by IDC Energy Insights shows that 83% of global mining companies will see their technology budgets increase. Considering the exponential explosion in technology development over the last decade, it would be no surprise if this figure is very close to 100% today. Many mining entities at the national level, including government, have explicitly spoken out on this issue in an open and positive manner.

Particularly as far as foundries are concerned, efforts have focused on several points, from new technologies for the furnaces (where the melting of raw materials is generated), to operational improvements at various points in the production process, such as the opening of passages.

This last process, in general, has a high manual workload for the operators, where the result and quality of the operation depends very much on the expertise of the operator. The operation itself can lead to a great deal of wear and tear on the components involved if the work is not carried out neatly, and a great deal of physical wear and tear on the personnel if the furnace conditions are not optimal for easy opening (a fact that is well known to anyone who works in this area of the furnace).

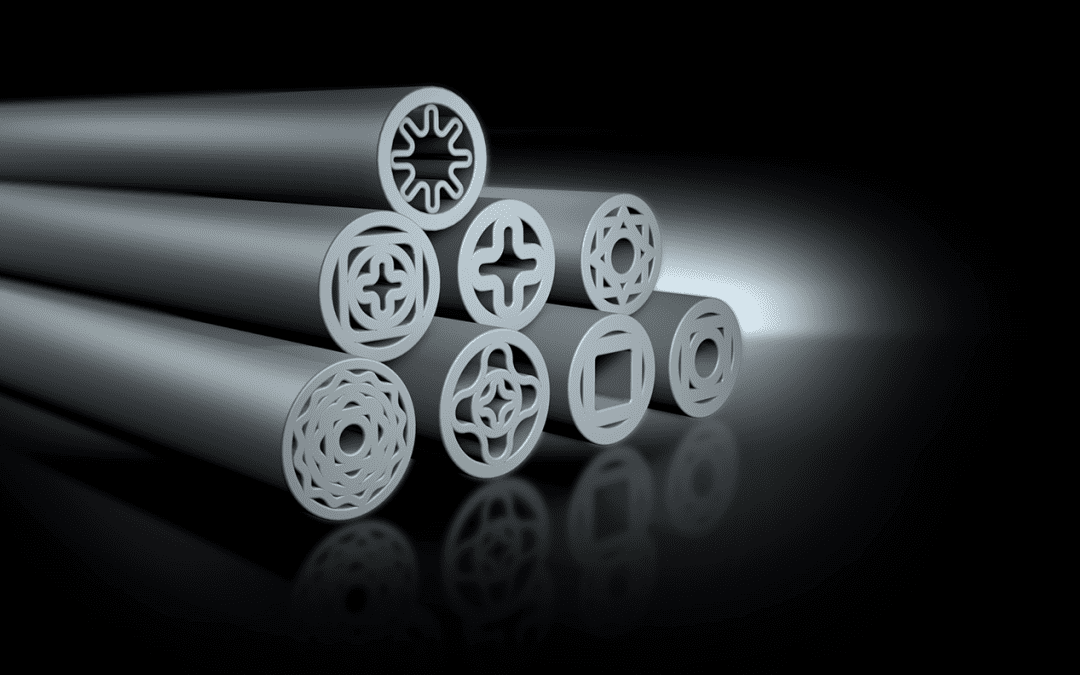

In response to this, Trefimet (a Chilean company) has developed the thermal lance in recent years. This product consists of an outer tube with several inserts, composed of tubular profiles on the inside that allow a greater amount of steel to enter the same area, focusing its energy once the thermal lance is turned on, which generates a more precise and faster perforation, compared to commonly used products (pipe or tubes filled with wires).

The design of these profiles allows the energy of the lance to be distributed for different jobs, with some being used for larger diameter bores, others for more precise bores and there are even those that allow for improved operating times (some models achieve the same job in a third of the time compared to common products such as pipes).

Although the process of opening passages is often seen as a minor operation within the macro process of foundries, the application of new technologies at this point of the process offers new improvements, both operational and production, by improving opening times, improving perforation profiles and extending the service life of the components involved (given their greater precision). In the near future, thermal lances will undoubtedly occupy a special place in the production process of most foundries seeking to keep up with the innovation train.