WE ARE LEADERS

IN TAPPING ENGINEERING

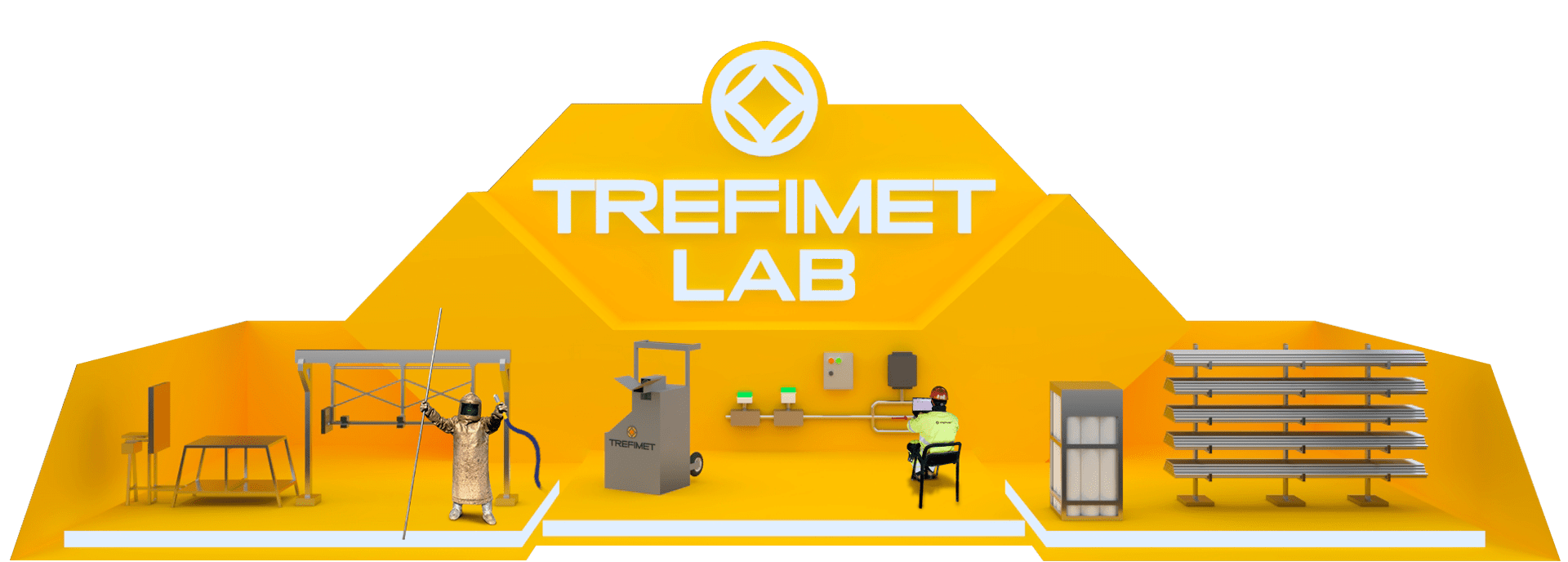

TEST TUBE AREA

Support area for the harsh conditions of tapping tests. In this area are located the specimens manufactured in Trefimet. Each one of them is manufactured and stored under the same conditions, in order to ensure the reliability of the results obtained during the tests.

TEST TUBE AREA

SPEAR RACK

Trefimet's laboratory is supplied with specimens of all the models of thermal lances manufactured by Trefimet. In this way, comparative tests are made between them to define performance, opening diameters, speed and other points to take into account when deciding on a lance to offer to a customer.

SPEAR RACK

TREFIMET Laboratory and its tests

Tapping zone:

Support area for the harsh conditions of tapping tests. In this area are located the test specimens manufactured in Trefimet. Each one of them is manufactured and stored under the same conditions, in order to ensure the reliability of the results obtained during the tests.

The guide system developed at Trefimet allows eliminating operating variables that could affect the reliability of the results obtained during the tests. This system also has protections to prevent incandescent material from splashing towards the operator, which considerably increases the safety of the overall testing operation.

The complete system is part of the intelligent opening prototype being developed and prepared by Trefimet for market launch.

One of Trefimet's latest developments. This device raises the temperature of the thermal lance tip and then, when fed with oxygen, it ignites to start tapping tests. It works on the induction principle and has a robust body, specially designed to withstand foundry working conditions. This product will be ready for commercialization soon.

Given the fundamental importance of feeding the thermal lances with the proper oxygen flow, Trefimet developed a system that has the ability to control the oxygen flow with which it is working, so that our engineering team can set the test flow to whatever is necessary. This equipment is developed to deliver the information in real time and retrieve the data for future analysis. Together with the tapping guide system, it is part of the intelligent opening prototype that Trefimet is developing and preparing to launch to the market.

To ensure a sufficient supply for testing, Trefimet has oxygen cylinder racks that are connected to the oxygen flow control system. With this system, it is possible to ensure the necessary oxygen flow at all times, both for tests with low and high oxygen requirement lances.

To ensure a sufficient supply for testing, Trefimet has oxygen cylinder racks that are connected to the oxygen flow control system. With this system, it is possible to ensure the necessary oxygen flow at all times, both for tests with low and high oxygen requirement lances.

Trefimet's laboratory is stocked with specimens of all the models of thermal lances it manufactures. In this way, comparative tests are made among them to define performance, opening diameters, speed and other points to take into account when deciding on a lance to offer to a customer.

Trefimet has an engineering team composed of multidisciplinary professionals trained in the use of thermal lances and with vast experience in foundries. Within this team there are chemical, electrical, mechanical and physical engineers. All of them are dedicated to the research and development of related products for the tapping process.

Designed to achieve the best performance that can be obtained from a Trefimet thermal lance. Easy and safe to operate and with a long service life. Suitable to work with all types of thermal lance.