How Trefimet looks for differences between its products and traditional pipes.

Within the development world, to release a final product, it is necessary to go through several rounds of testing, where each is designed to speak to a feature of the product itself.

At Trefimet, this is a common practice, where products are tested in its metallurgical laboratory to determine their performance. For this, perforation tests are carried out with a system developed to control the different variables that may influence the final result, in such a way that the perforation itself only depends on the thermal lance to be used. The specimens used for these tests are manufactured in an area annexed to the laboratory under the same conditions, so that, at the time of the test, they all have the same composition, dimensions and even humidity level.

During the drilling test, different measurements are made for later comparisons, such as working time, oxygen flow rate feeding the thermal lance and oxygen pressure among others. These measurements, combined with those taken after the test, give the engineering team an idea of the performance that a thermal lance could have under foundry conditions.

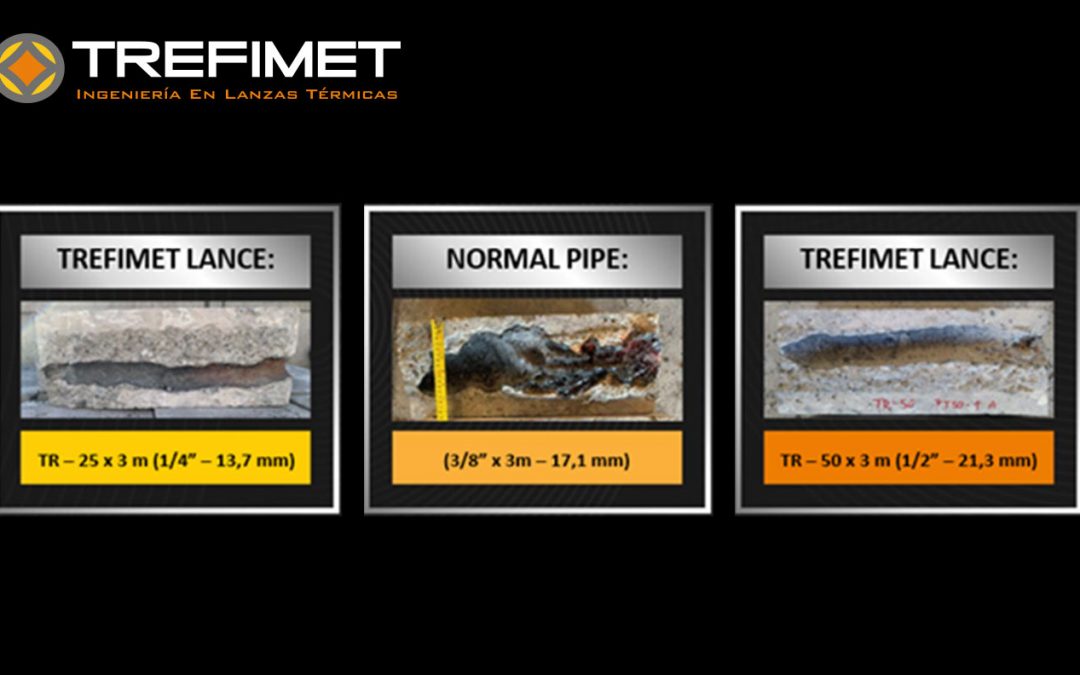

Once the test has been performed, the specimens are cut in half, in order to make a visual inspection of the result and take measurements to determine opening diameters, regularity of the perforation and how the phenomenology of the different stages of the test can affect the final result.