How does the Trefimet thermal lance contribute to this work?

Within smelters there are countless processes where a small "misstep" can cause considerable delays in the overall operation. These situations are diverse and many of them come without warning, from a malfunction in the acid plant in a copper smelter to a pig iron cut-off (accretion) in a blast furnace, management has to stop production for up to several days in some cases.

Text box: In the case of maintenance and cutting operations of accretions and blockages, the speed of the operation becomes fundamental, increasing the days of detention in function of the days that the maintenance or cutting operation takes. This is why it is essential to have fast cutting tools for this type of situation.

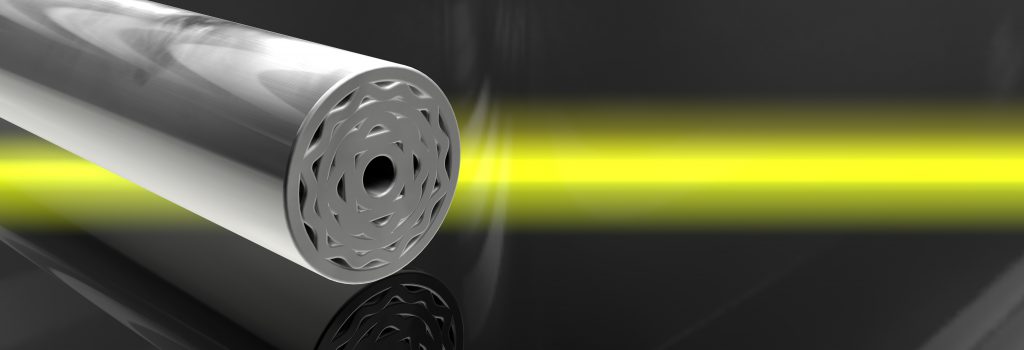

There is a wide range of Trefimet thermal lance models for this task, where the configuration of the lance and the diameter to be used is chosen according to the size of the accretion to be cut, the type of material and the type of operation to be carried out. Trefimet thermal lances have been used for demolition and maintenance works in several places around the world (Europe, Scandinavia, South America, etc.), allowing, in some cases, to save up to days of operation due to their speed when cutting.

The biggest advantage over traditional lances is the speed with which they perform this task and the ease with which they can melt even the hardest materials thermally speaking, which allows operators to manoeuvre easily in the cut and evacuate the molten material more easily to continue the operation.

The consumption rate of these lances and their steel configuration allow them to deliver more than adequate power to melt the most difficult to cut materials, such as copper, for example, where its high thermal conductivity works against them when trying to concentrate thermal energy in one point.

In addition to offering specialised thermal lances for cutting, Trefimet offers training services and on-site support for this type of operation, as well as providing the best treatment when supplying its products, with the ideal being to maintain a back-up stock for unforeseen cases where these operations are required.