How does the Trefimet thermal lance contribute to this work?

In the foundry industry there are innumerable processes that are bottlenecks and that have a great relevance in the operation in general, but among them, there is undoubtedly one that occupies a very special place, and that is the process of bleeding the metal and slag passages in the smelting furnaces.

This process is responsible for allowing the evacuation of the molten material from inside the furnace for subsequent processes. This process is commonly carried out with oxygen tubes or pipes, a tool to which much of the responsibility is attributed for the damage caused to the different components of the passages, a phenomenon inherent to the use of these, such as damage to graphite inserts, refractory bricks, cooled plates, etc.

In parallel to the traditional oxygen lances, such as the steel tube or the tube filled with wires (oxyflame), there are more sophisticated tools, which use the same principle to work (combustion of the steel that composes them), and these are the Trefimet thermal lances.

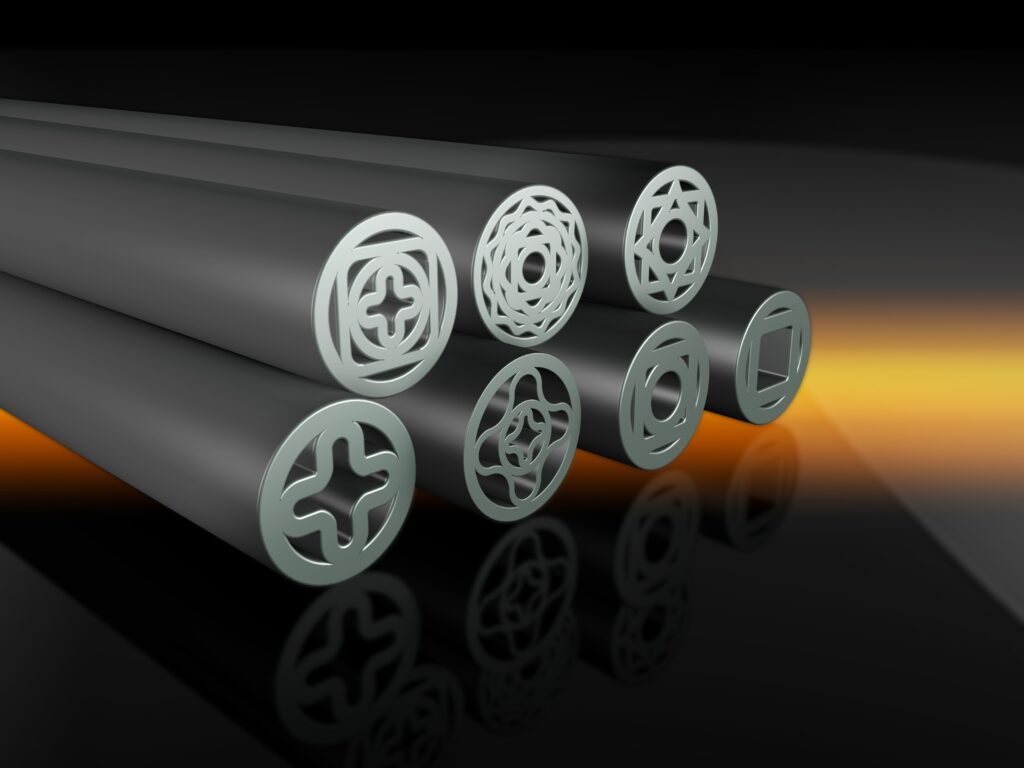

Trefimet thermal lances are primarily used to open furnace passages. This new development of nozzles has evolved to generate a significant range of nozzles, which are capable of maximising thermal energy utilisation according to the variables of the operation required, i.e. the right nozzle against a variety of "greda" plugs, at different opening diameters and available oxygen pressures, etc.

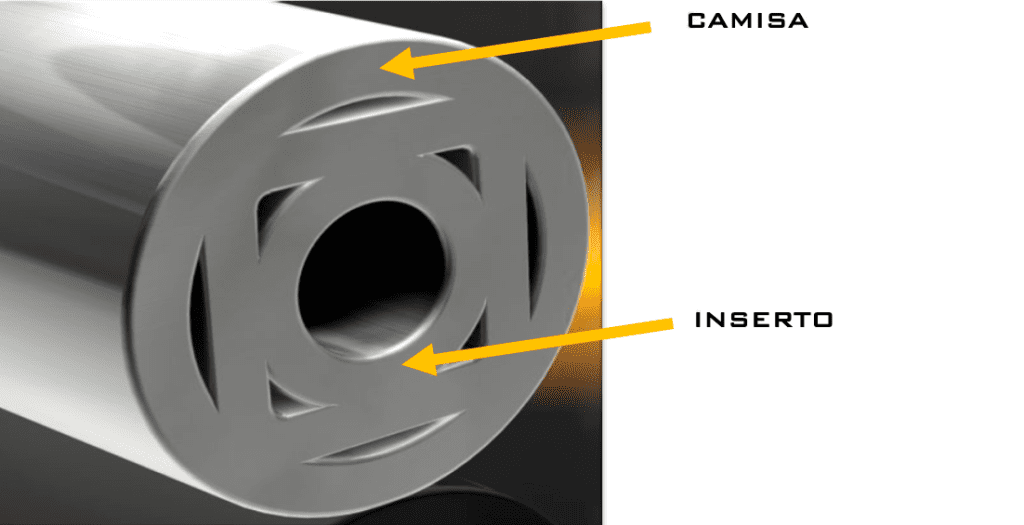

Compared to the traditional product, the Trefimet thermal lances present substantial differences that result in a more precise operation, contributing to the careful handling of the taphole. To explain their differences, it is necessary to go deeper into the design and operation of these tools. The operation of a thermal lance or an oxygen tube or pipe is based on the combustion of iron in contact with oxygen at a temperature of 870°C.

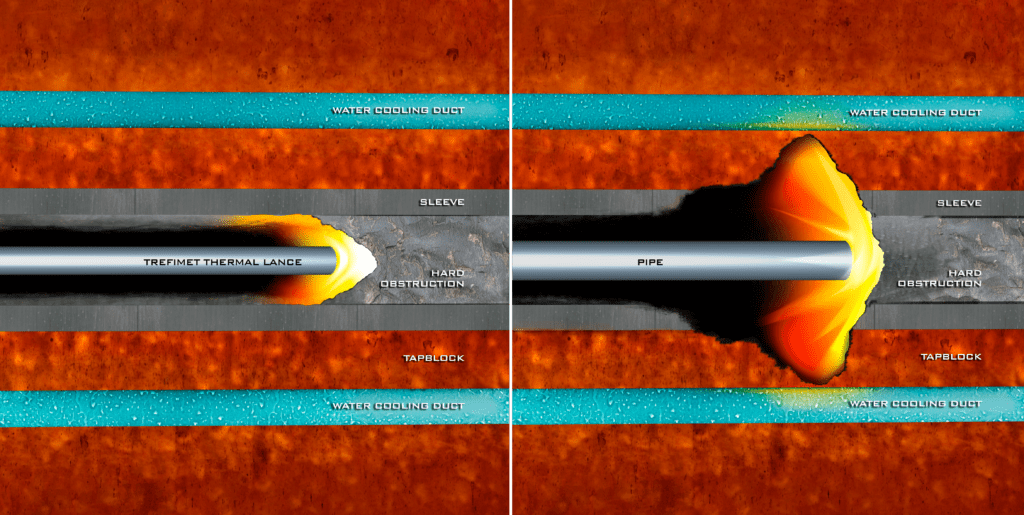

In the case of oxygen pipes, the effective energy is at the perimeter of the pipe; therefore, there is no energy in the cross section, so much of the energy will be projected radially. Additionally, as most of the unburned oxygen is allowed to pass through, the attack zone is cooled, hindering the advance of the oxygen tube and causing it to deflect, increasing radial damage. The configuration of these tubes allows only the inner periphery of the tube to have contact with oxygen, making it difficult to maintain the self-sustaining reaction. To maintain combustion, it is necessary to press the pipe with force against the taphole/passage, exerting this force to achieve an increase in temperature and pressure at the tip of the oxygen pipe, so that it remains in combustion. However, this temperature increase in a larger pipe section increases the combustion length by projecting the energy radially instead of axially, resulting in uncontrolled combustion in the passage. The radial direction of the oxygen tube energy melts sections of the walls of the passageway components that must not be damaged.

The Trefimet thermal lance, on the other hand, is formed by inserts that allow a larger contact area with the oxygen, causing the reaction in the cross section of the lance. In turn, when both surfaces are in contact with oxygen, there is a higher reaction rate; therefore, the lance inserts burn faster than the outer tube. However, as these lances operate inside the passage, due to the rebound effect, the outer tube achieves the same burn rate as the inserts. In this way, the energy projection of a Trefimet thermal lance takes an axial direction, which allows for more precise work and shorter operating times.

Finally, using a Trefimet thermal lance under optimal operating conditions, a substantial difference in the opening profile of the passage is achieved, even in the face of blockages in the passage (pieces of electrodes or refractory bricks).

Independently of the advantages regarding the care of the components of the passage, the use of Trefimet thermal lances, shows operational and economic advantages, directly related to its use, such as the decrease in operation times, the increase of the safety standard for the operators and product of being less "harmful" for the taphole, allows to obtain a longer life time of the components of the bleeding zone, ensuring a greater availability of equipment, being a great contribution to the productivity of the operation.