How the care of the passage is related to this concept and the role of thermal lances in this task…

Maintaining the Passage (Tap Hole) is essential for the effective operation of the smelting furnace, as it allows adequate drainage of the furnace with minimal operator interference.

A worn out passage can lead to a more violent flow, significantly increasing fumes emissions during tapping and will risk mixing and losing more metal to the slag. Over time, side ducts can form and damage the liner around the tapping area. This can turn into a major operational problem and damage the plates, resulting in a significant safety risk and causing significant production losses. All this adds to the loss of availability of the tapping station due to maintenance, which often makes it necessary to stop the smelting furnace, reducing the overall productivity of the total operation.

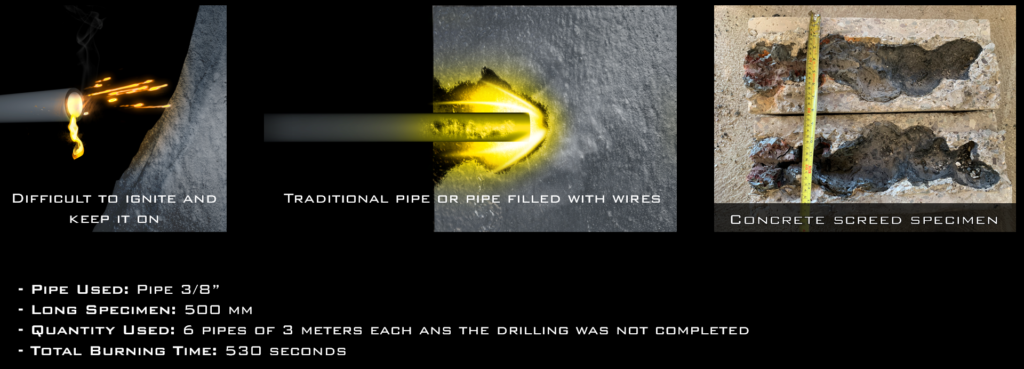

Commonly, a large part of the responsibility for wear in the different components of the tapping area (graphite inserts, refractory bricks, cooling plates, etc.) is attributed to the use of traditional oxygen lances (pipes and pipes filled with wires).

As they are low precision tools, their performance and standardization in the operation depends a lot on the operator’s expertise, which, in the same way will generate damage to the passage and an increase in the need for maintenance by it.

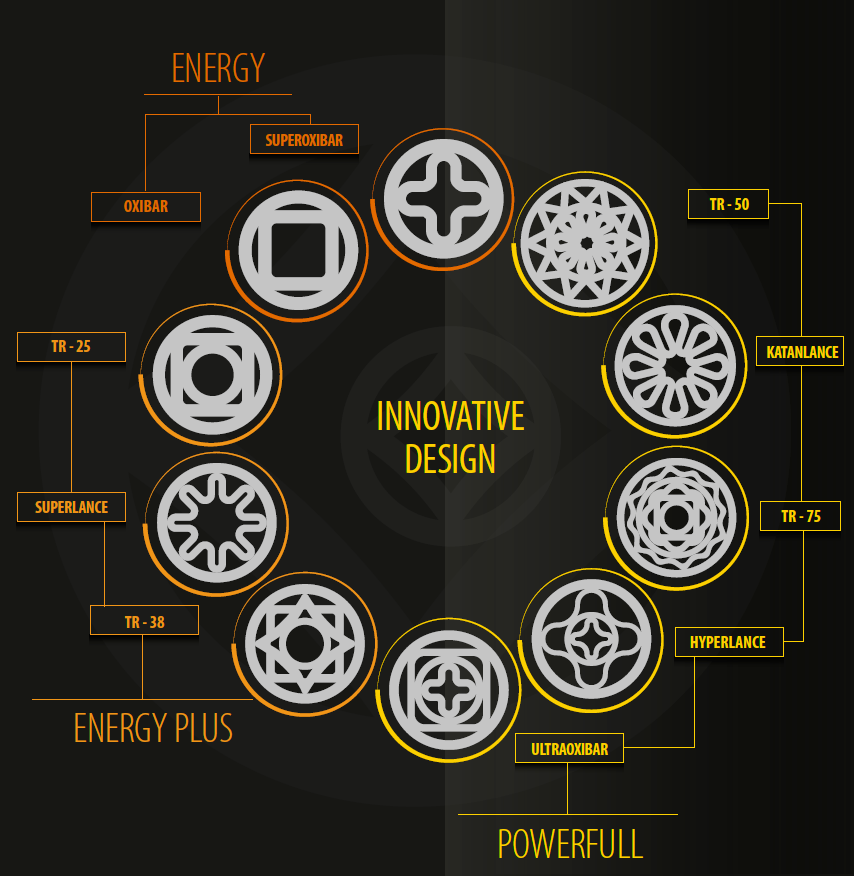

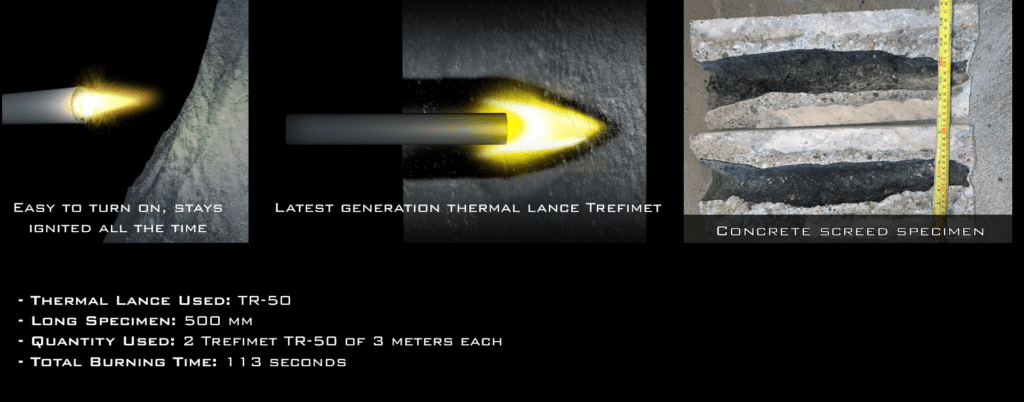

To overcome this problem, it is necessary to use tools of greater precision and that do not have such a high dependence on the skills of the operators or the working conditions of the furnaces. Given this, the Trefimet thermal lances comply these characteristics.

The Trefimet thermal lances by stay ignited all times, can advance through the passage without the need to maneuver with them or exert excessive effort, only maintaining contact between the lance and the material to be melted. This advantage allows the operator to align the thermal lance with the central axis of the passage, which minimizes the possibilities of generating new tapping passages adjacent to the original and damage/perforations in graphite inserts and cooling plates.

Additionally, the Trefimet thermal lances are characterized by being tools of focused thermal energy, which allows a fast and precise operation. Due to this last point, this tool can pass through the passage to the material to be evacuated, only melting the plug and the product that remained in the passage of the previous tapping, generating more even opening profiles and increasing the useful life of the different components of the tapping zone.

Undoubtedly, these advantages allow to standardize and ensure a precise and fast operation, removing the impact that the expertise of the operators can generate about the passage and its useful life. The greater availability of the equipment, better control of the bleeding operation, reduction of opening times and lower operating expenses related to the maintenance of the tapping area, have a direct impact on the general production of the furnace, and, therefore, of the entire furnace operation.